At SCGC, we are at the forefront of the green transition, engineering sustainable polymers and circular economy solutions that redefine modern industry and elevate quality of life.

Our operational excellence is rooted in a deep commitment to the ESG framework and the UN's 17 SDGs. We develop advanced materials and High Value-Added (HVA) products crucial for future-forward sectors like smart infrastructure, sustainable packaging, and clean energy. By relentlessly pursuing chemical innovations, we not only drive economic growth across Thailand and ASEAN but also build a better, more sustainable world for all.

To achieve sustainable growth in today's demanding market, petrochemical leaders must master three interconnected pillars: continuous innovation, superior performance and cost efficiency, and a deep commitment to the circular economy. As industry analysis from firms like Deloitte has confirmed, the single most crucial catalyst for success across these areas is the strategic adoption of industrial digitalization.

At SCGC, we embody this blueprint. Our strategy for operational excellence is a living example of this framework in action. As ASEAN's leading integrated chemical player for sustainability, we leverage cutting-edge digital tools to:

SCGC's operational excellence is a strategic journey that transforms data into decisive action—from predicting market trends and equipment needs to protecting our people, assets, and the environment. Our AI-driven operations are designed to deliver performance at every stage.

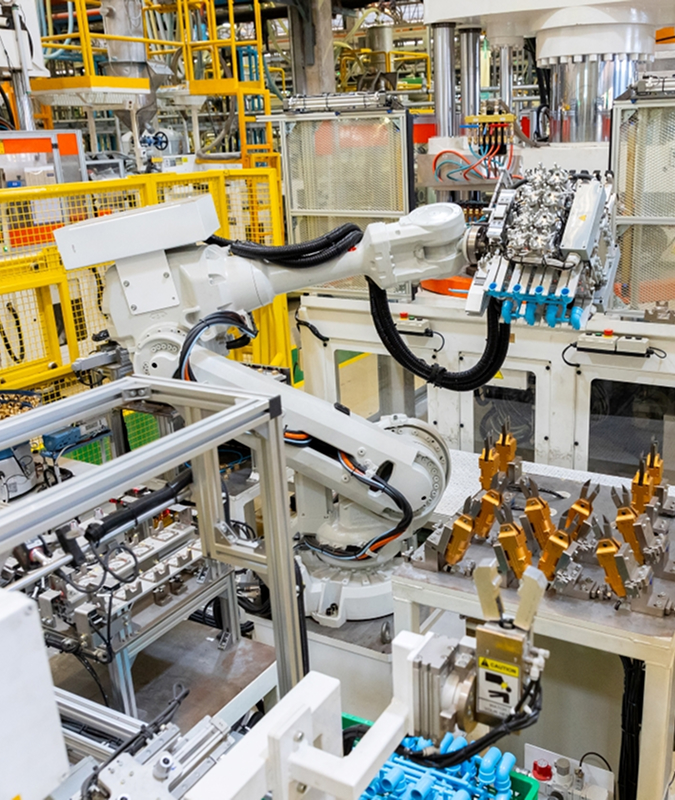

We leverage sophisticated machine learning algorithms to forecast feedstock markets, ensuring optimal sourcing. Internally, our Digital Reliability Platform acts as a powerful predictive tool, monitoring the health of our assets around the clock to preemptively address maintenance needs and prevent costly downtime.

Our Digital Twin technology provides a virtual replica of our production processes, enabling us to test, adapt, and perfect operations without interrupting workflow. This powerful simulation capability maximizes efficiency, reduces waste, and ensures we deliver the highest quality products consistently.

The AI Supervisory for Energy Analytics provides our operators with real-time guidance to enhance energy efficiency and minimize our carbon footprint.

By developing proprietary machine learning algorithms, we gain a critical edge in forecasting market trends. This technology provides our team with predictive intelligence to optimize raw material sourcing and precisely match customer needs.

At SCGC, our operational excellence is driven by a powerful, end-to-end digital strategy that enhances everything from customer service to innovation. The cornerstone is our proprietary Digital Commerce Platform (DCP), an integrated system that connects customer orders directly with our supply chain management data. This provides our customers with seamless, real-time order tracking and has successfully reduced customer response times by 70%.

The data from our DCP fuels deeper value chain optimization. This is complemented by our market intelligence tools, which use predictive analytics to guide our raw material sourcing, ensuring our procurement strategy is both cost-effective and perfectly aligned with dynamic market conditions.

This commitment to digital efficiency also accelerates our new product development (NPD). By leveraging advanced production simulation models, we drastically shorten development cycles and bring innovative products to market faster. This holistic digital strategy—from intelligent sourcing to enhanced customer service and rapid innovation—is how SCGC sets a new benchmark for efficiency in the chemical industry.

SCGC's leadership in innovation is spearheaded by our i2P Center (Ideas to Products), an integrated innovation hub designed to deliver results. Supported by a global network of partners, we collaborate directly with clients and brand owners to streamline the entire development process—from initial R&D and design to rapid prototyping and testing.

Our focused approach eliminates barriers and accelerates progress, ensuring a faster path to market for groundbreaking products and solutions. With a robust pipeline of over 100 active innovation projects, the i2P Center is where SCGC's vision for a better future is actively being built today. This is innovation in action.

Petrochemicals are essential not only as building blocks for everyday materials but also as a cornerstone for any developing economy seeking to enhance living standards and strengthen key domestic and export industries.

With an annual capacity to produce 1.35 million tonnes of olefins, 1.4 million tonnes of polyolefins, and 1 million tonnes of other by-products, LSP will significantly reduce the country’s reliance on imported plastic resins that are essential for a wide range of downstream industries - including packaging, electrical appliances, medical devices, agriculture, construction, automotive, etc. —thereby enhancing the competitiveness of local downstream businesses and contributing to Vietnam’s economic prosperity.

As LSP embarks on its operational journey, it highlights a successful collaboration between SCG, SCGC, and the Vietnamese government. This partnership has created Vietnam’s first integrated petrochemical complex, marking a major milestone in industrial growth. It demonstrates how working together can achieve great results and set the stage for future success and mutual benefit.

Innovation that fits your needs.

Insights that inspire.

Join our growing team.